SYM tower crane S480 LH24 Luffing tower crane.

Luffing boom tower crane.

Free standing height 63m luffing tower crane.

Jib 60m luffing tower crane.

Tip load 5 ton luffing tower crane.

24 ton capacity.

2.5x2.5x6m tower crane mast section.

Hoisting motor 90kw x 1

Slewing motor 9kw x 3/145NM x 3.

Trolley motor 75kw x 1.

Mechanisms | Diagram | Technical features |

Hoisting |

| Adopt frequency conversion motor,fast speed and high torque.The special software for hoisting is applied to ensure that tower crane does not slip out of the hook at the moment of startup. Double contactor holding brake protection Brake failsafe (hover function). |

Trolley |

| Adopt frequency conversion motor, run smoothly and without impact.It is suitable for prefabricated buildings to achieve low-speed operation and accurate positioning of items. |

Slewing |

| Special software prevents the boom from shaking and ensures smooth rotation. One-button wind indicator: In the case of strong winds, the swing brake is released in time. |

Travelling |

| One drag multi-frequency VF control, make the traveling run more smoothly. |

Control panel |

| The main components use the Schneider brand, including frequency converters. The control cabinet has two kinds of shells: stainless steel and iron plate.The overall installation of the plate, the direct riveting of the spare cap, the components are more firmly fixed. Standardize the wiring in the cabinet to reduce the occurrence of wiring faults. |

Marks |

| ①A traceability code is attached to the outside of the control cabinet. ②The control cabinet is tested before delivery,and the qualified mark. ③The cabinet door is affixed with company logos and warning and reminder marks. ④Electrical drawings puts in the control cabinet. |

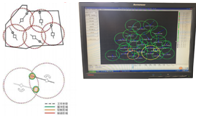

Anti-collision system |

| Collision protection between towercranes, and the tower crane bodyboom or hook collides with other mobile equipment. Area protection,setting the workingrange of tower cranes. |

Intelligent manufactory |

|

Limit switch. Load limiter. Torque limiter prevent overload for different radius. Load moment indicator. |

Remote monitoring |

| Automatically track the operation of the hook and monitor the lifting status in real time. Monitor the rope arrangement of the drum. Other positions that need to be monitored. |